List of tutorials

All tutorials are written assuming that you are reasonably familiar with MOOSE. If you find most of the tutorials difficult to follow, please refer to the official MOOSE website for learning resources.

Tutorial 1: Small deformation elasticity

This tutorial covers the basic usage of RACCOON.

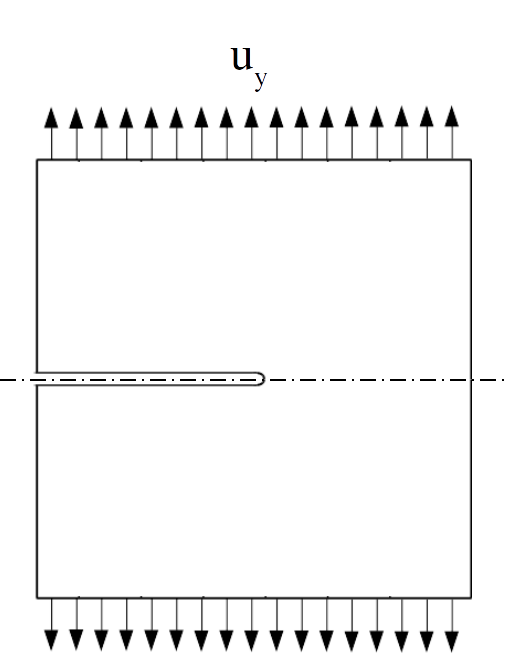

Consider a two-dimensional square plate with a notch (the commonly used geometry for Mode-I fracture) under stretch, we would like to solve for the displacements and visualize its strains and stresses everywhere.

Figure 1: Geometry and boundary conditions of the Mode-I crack propagation problem.

Global expressions and parameters

It is always good practice to define parameters using expressions at the top of the input file. Here, we first define two expressions for Young's modulus and Poisson's ratio:

E = 2.1e5

nu = 0.3

Next, we convert and to bulk modulus and shear modulus using brace expressions:

K = '${fparse E/3/(1-2*nu)}'

G = '${fparse E/2/(1+nu)}'

For our convenience, let's also define the global parameter displacements as that is required by several objects, e.g. ADStressDivergenceTensors, ADComputeSmallStrain, etc.. GlobalParams definitions will be applied wherever applicable throughout the input file, unless locally overridden.

[GlobalParams]

displacements = 'disp_x disp_y'

[]

Mesh

Let's utilize symmetry about the x-axis so that we can get away with only modeling the top half of the domain:

[Mesh]

[gen]

type = GeneratedMeshGenerator

dim = 2

nx = 30

ny = 15

ymax = 0.5

[]

[noncrack]

type = BoundingBoxNodeSetGenerator

input = gen

new_boundary = noncrack

bottom_left = '0.5 0 0'

top_right = '1 0 0'

[]

construct_side_list_from_node_list = true

[]

Notice that we defined an extra nodeset/sideset called "noncrack", so that we can later apply the symmetry condition.

Variables and AuxVariables

In this problem we solve for displacements in the x- and y- directions, hence we define

[Variables]

[disp_x]

[]

[disp_y]

[]

[]

In addition, we define auxiliary variables fy and d:

[AuxVariables]

[fy]

[]

[d]

[]

[]

The AuxVariable fy will store residuals associated with Variable disp_y. Later, we will use it to compute the reaction force.

The AuxVariable d is a dummy variable representing the phase-field that is zero everywhere. In this tutorial, it will stay zero.

Kernels

Kernels are arguably the most important objects in an input file. They define the equations we are solving for. In this case, we solve for

without any body force.

Kernels are defined as

[Kernels]

[solid_x]

type = ADStressDivergenceTensors

variable = disp_x

component = 0

[]

[solid_y]

type = ADStressDivergenceTensors

variable = disp_y

component = 1

save_in = fy

[]

[]

We are solving a vector-valued equation, and the two kernels correspond to the two components, respectively.

Boundary conditions

Boundary conditions are shown in Figure 1: only the top half of the domain is modeled utilizing symmetry. On the bottom of the computational domain, i.e. a nodeset named "noncrack" is generated and used to define the symmetry condition. A displacement-controlled Dirichlet boundary condition is applied on the top. In the input file, these boundary conditions correspond to

[BCs]

[ydisp]

type = FunctionDirichletBC

variable = disp_y

boundary = top

function = 't'

[]

[yfix]

type = DirichletBC

variable = disp_y

boundary = noncrack

value = 0

[]

[xfix]

type = DirichletBC

variable = disp_x

boundary = top

value = 0

[]

[]

The y-displacement on the top boundary is set to be equal to the time t. In this quasi-static setting, we can use time as a convenient dummy load-control parameter.

Material models

The material is assumed to be isotropic elastic under small strain assumptions. First, the homogeneous shear and bulk modulus are defined everywhere (at every quadrature point):

[Materials]

[bulk]

type = ADGenericConstantMaterial

prop_names = 'K G'

prop_values = '${K} ${G}'

[]

[]

Since we don't consider any fracture coupling, a dummy NoDegradation degradation function is defined as

[Materials]

[no_degradation]

type = NoDegradation

property_name = g

expression = 1

phase_field = d

[]

[]

Then, the Materials section is completed by the definition of the strain calculator, the constitutive relation, and the stress calculator:

[Materials]

[bulk]

type = ADGenericConstantMaterial

prop_names = 'K G'

prop_values = '${K} ${G}'

[]

[no_degradation]

type = NoDegradation

property_name = g

expression = 1

phase_field = d

[]

[strain]

type = ADComputeSmallStrain

[]

[elasticity]

type = SmallDeformationIsotropicElasticity

bulk_modulus = K

shear_modulus = G

phase_field = d

degradation_function = g

output_properties = 'elastic_strain'

outputs = exodus

[]

[stress]

type = ComputeSmallDeformationStress

elasticity_model = elasticity

output_properties = 'stress'

outputs = exodus

[]

[]

Notice that we have requested to output elastic_strain and stress to exodus. Since they are RankTwoTensors, we will find elemental variables with names like elastic_strain_00 and stress_22, denoting their corresponding component.

It is imperative to understand that, in MOOSE, MaterialProperties are computed on-thy-fly. Material dependency is automatically resolved by MOOSE.

Postprocessors

Finally, we add a postprocessor to sum the nodal values of fy along the top boundary to give us the reaction force in the y-direction:

[Postprocessors]

[Fy]

type = NodalSum

variable = fy

boundary = top

[]

[]